Overview

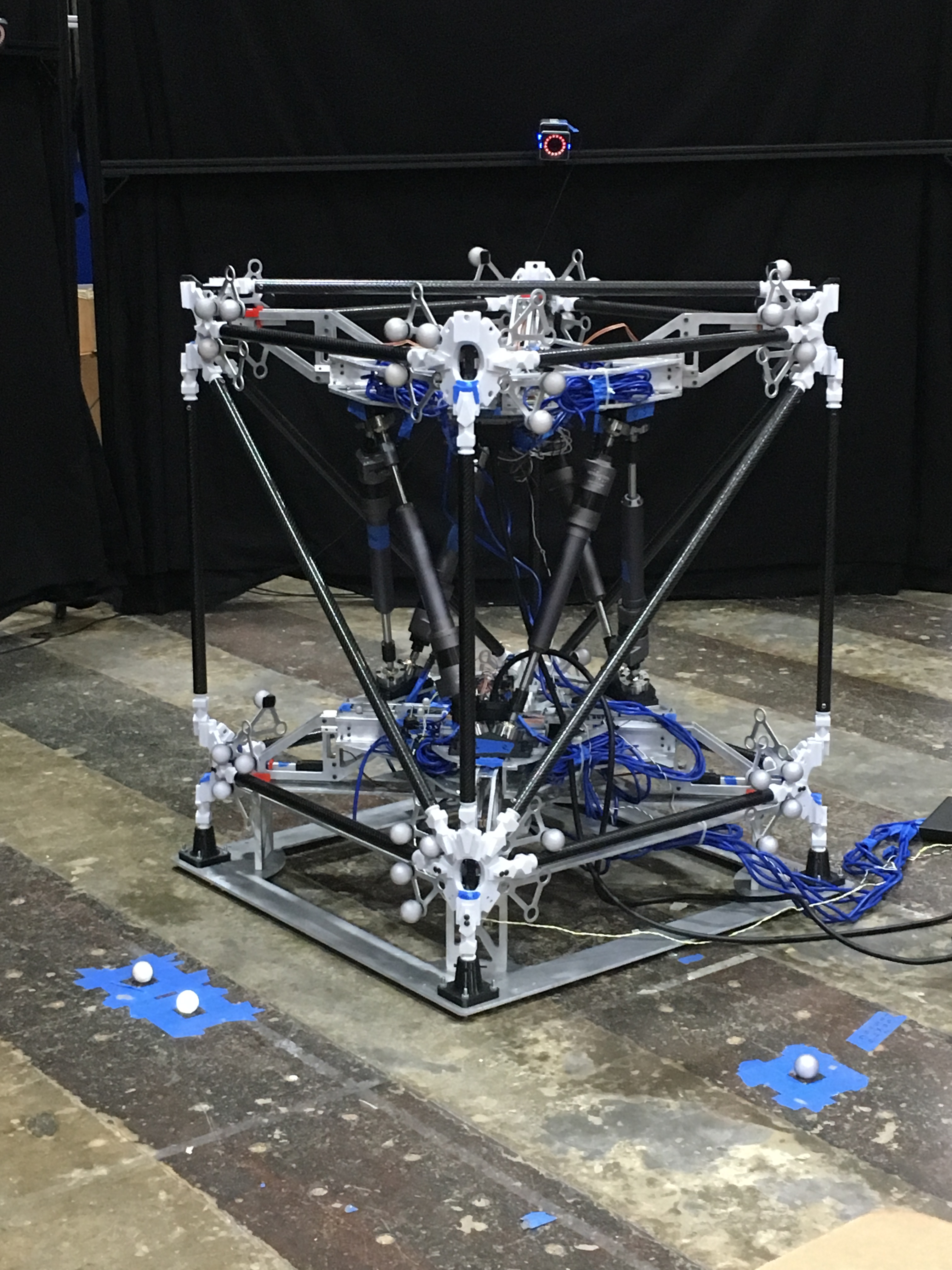

During the winter of 2017, I interned at the NASA Langley Research Center. I joined the Commercial Infrastructure for Robotic Assembly and Services Team as an electrical engineering intern. The main objective for this team was to build a system for Orbital ATK that could robotically build a large truss structure in space. The general process of assembling the truss starts with a 40 ft robotic arm picking up an individual strut from a storage bin. Then, the robotic arm places the strut in the jigging robot. This process is repeated until one section or “cube” of the truss struts have been placed in the jigging robot. Next, the jigging robot precisely manipulates all the struts to get them into the correct alignment. A secondary robotic arm with an electron beam welder then comes in to weld each joint together. This completes one section of the truss. The jigging robot now disconnects from that section of the truss and moves to the next section.

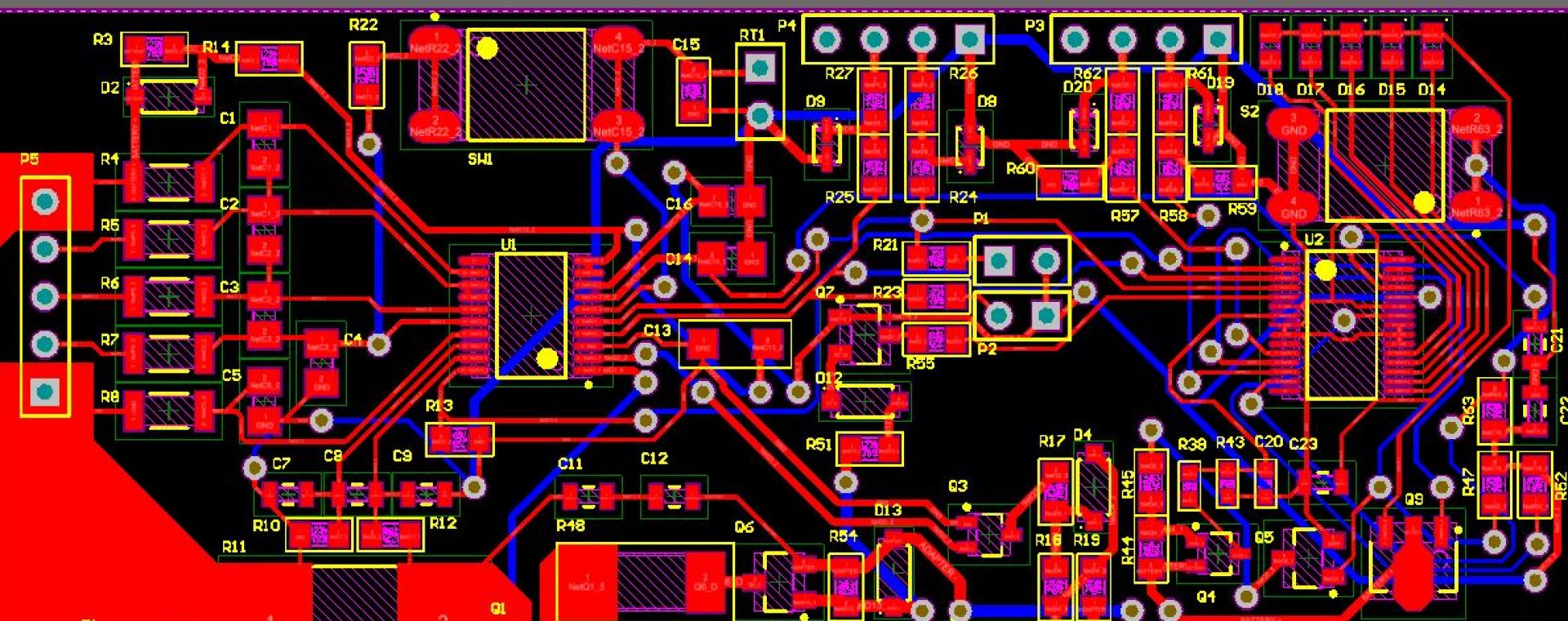

During my time on this project, I was given the responsibility of designing the jigging robot. I used 6 linear actuators to form a hexapod to allow for six degrees of freedom (DOF) between the upper and lower sections of the truss section. Using 16 more actuators, I gave each node of the truss section 2 DOF. Once I had developed a model of how I would position all the nodes correctly, I then designed a laser sensor system to act as a feedback control system for the linear actuators. I developed this feedback system to run on a real time computing system in Simulink using a Speedgoat computer. This was an exciting project to work on, and over a few months I was able to complete a design for the jigging robot.